TECHNOLOGICAL PROCESSES

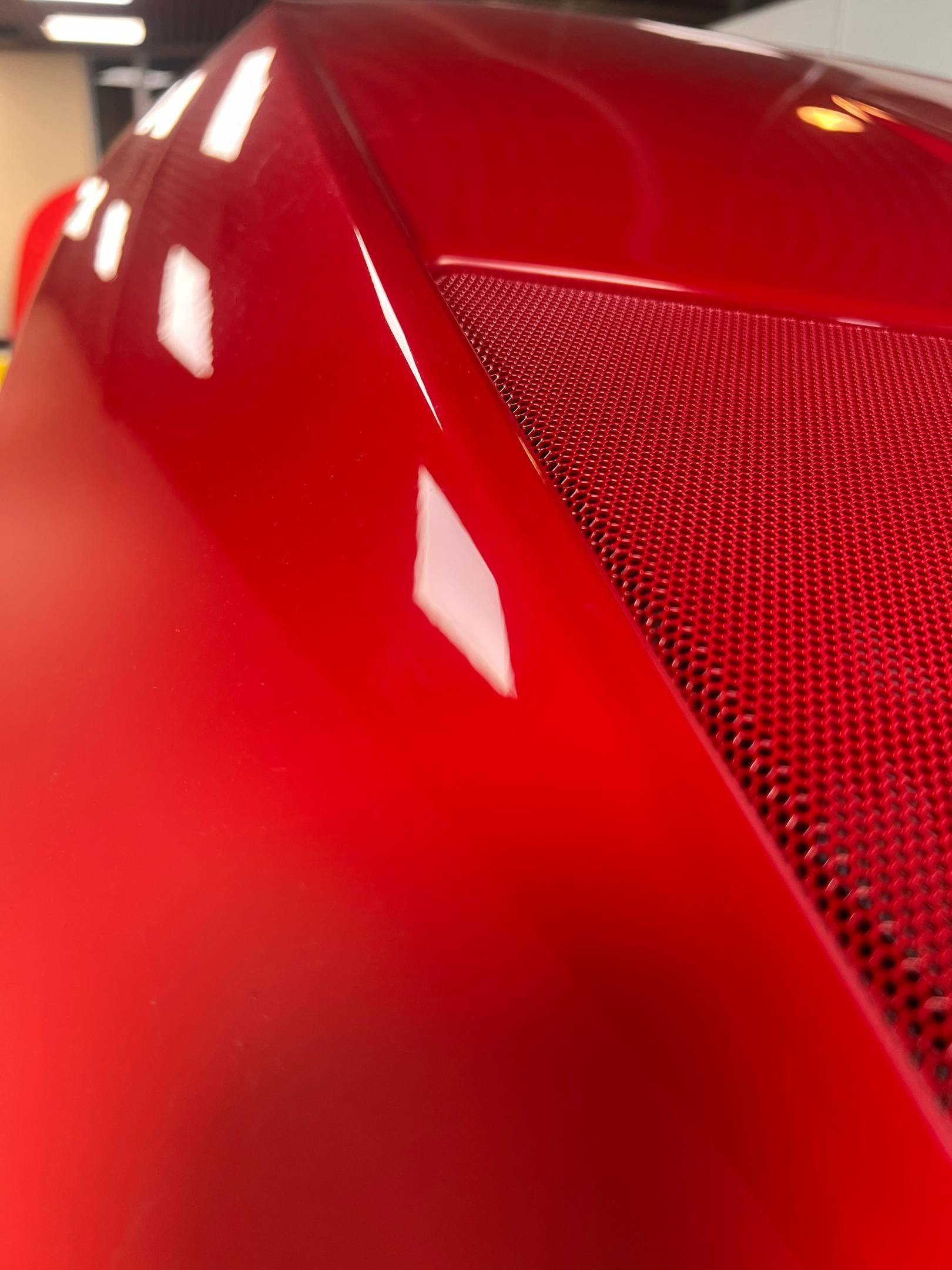

RIM - pDCPD

RIM - pDCPD

Polirim uses pDCPD moulded by RIM (Reaction Injection Molding) technology,

to offer a series of advantages to a wide range of industrial applications.

Its main characteristics are:

• Optimal balance between resilience and stiffness: PDCPD provides an excellent balance between flexibility and robustness

• High impact resistance even at low temperatures: it maintains its structural integrity and functionality even in extreme thermal conditions -40° <T<130°

• Excellent resistance to chemical agents: effectively resists the corrosive action of many chemical substances, prolonging the life of the components made

• Dimensional stability: guarantees precision and reliability over time

• Low specific weight: with a low weight, it is ideal for applications where weight is a critical factor

• Fast Production Cycles: RIM technology enables fast production cycles, increasing efficiency and reducing cost.

• Excellent surface quality and easy paintability: PDCPD guarantees a high level of paintability

• Aluminum moulds: guarantee precision, lightness and durability, helping to reduce costs and time to market

• Low environmental impact and energy consumption molding: our processes are designed to be environmentally sustainable, minimizing energy use and reducing the carbon footprint

to offer a series of advantages to a wide range of industrial applications.

Its main characteristics are:

• Optimal balance between resilience and stiffness: PDCPD provides an excellent balance between flexibility and robustness

• High impact resistance even at low temperatures: it maintains its structural integrity and functionality even in extreme thermal conditions -40° <T<130°

• Excellent resistance to chemical agents: effectively resists the corrosive action of many chemical substances, prolonging the life of the components made

• Dimensional stability: guarantees precision and reliability over time

• Low specific weight: with a low weight, it is ideal for applications where weight is a critical factor

• Fast Production Cycles: RIM technology enables fast production cycles, increasing efficiency and reducing cost.

• Excellent surface quality and easy paintability: PDCPD guarantees a high level of paintability

• Aluminum moulds: guarantee precision, lightness and durability, helping to reduce costs and time to market

• Low environmental impact and energy consumption molding: our processes are designed to be environmentally sustainable, minimizing energy use and reducing the carbon footprint

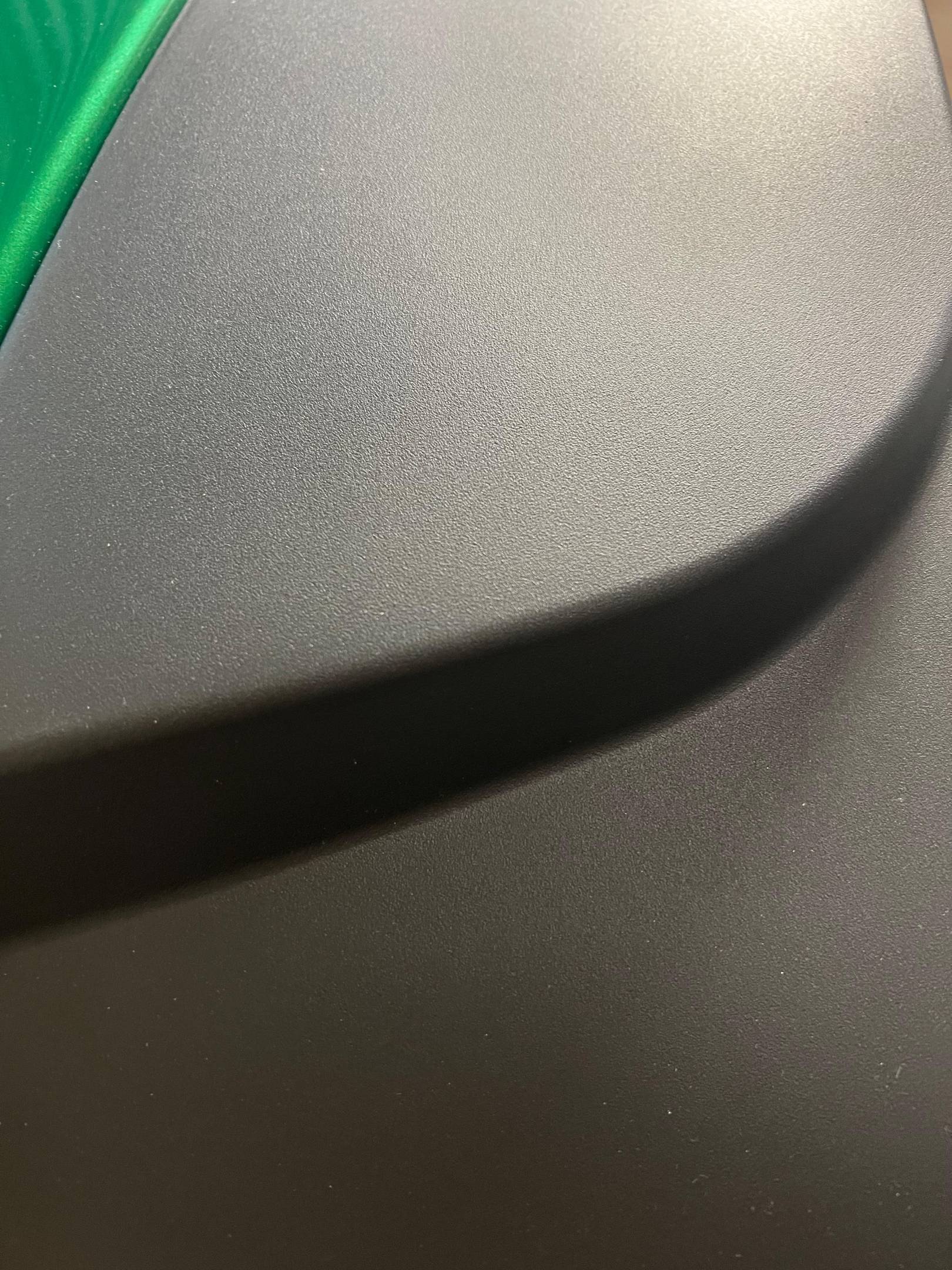

RIM - PU

RIM - PU

RIM-PU technology is at the forefront of the elastomeric polymer sector.

Here are the main characteristics of this extraordinary material:

• Elastomeric polymer with high mechanical characteristics: guarantees excellent performance in applications that require resistance and durability

• Elongation at break of 200%: offers considerable elasticity, allowing the material to stretch without breaking, ideal for dynamic applications

• Dimensional stability: maintains its size and shape even under stress and temperature variations, ensuring precision and reliability in the final products

• Impact resistance: Designed to absorb and dissipate energy, protecting components and improving product longevity

• Mass black coloring: integrated coloring ensures a uniform appearance and greater resistance to scratches and wear, reducing the need for additional surface finishes

• Excellent surface quality: the material finishing is uniform and can be textured in mold improving the aesthetics of the final product

• Aluminum Molds: We use high-quality aluminum molds that offer precision and repeatability, contributing to efficient manufacturing processes and high-quality results

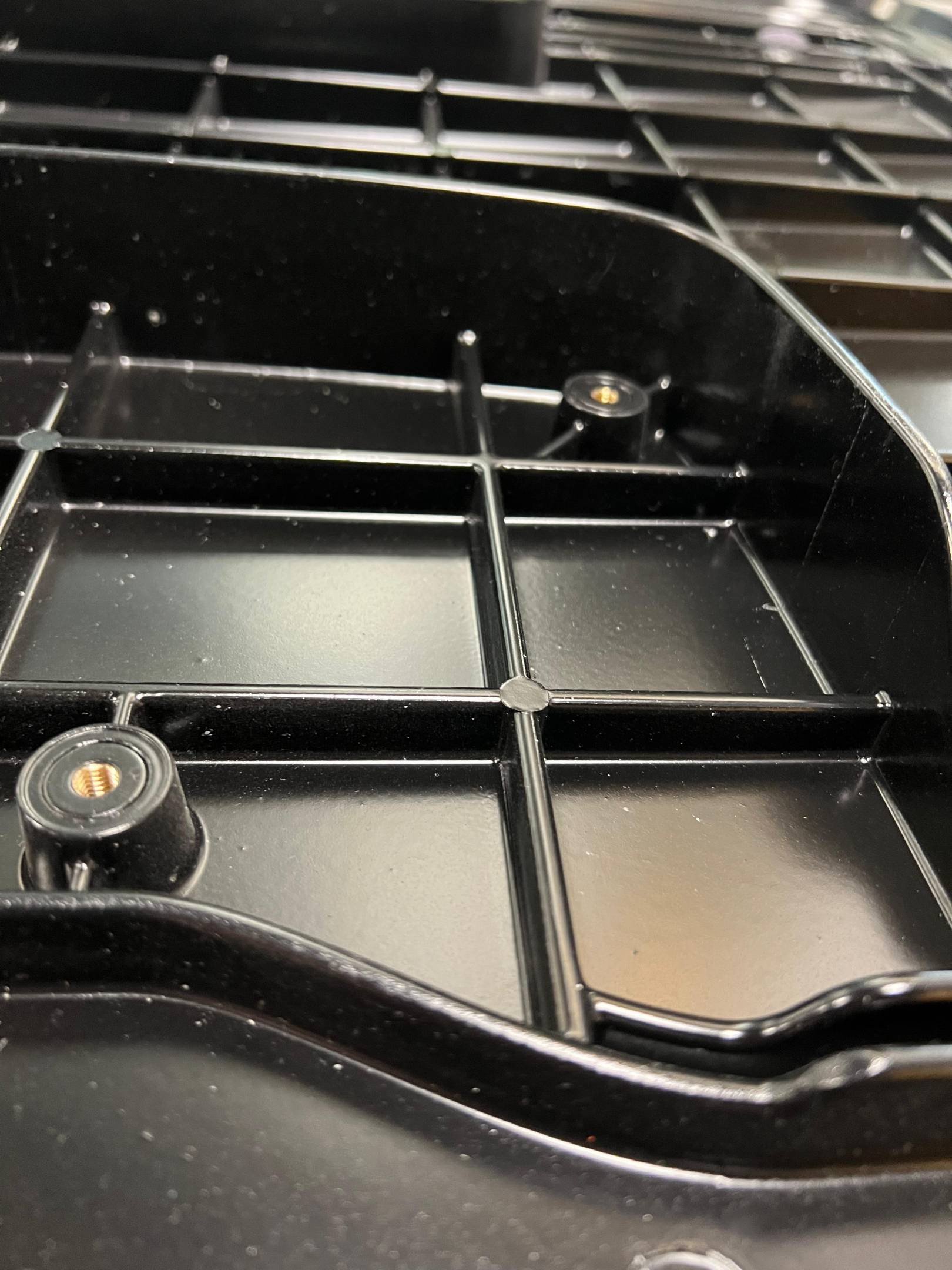

Sheet Moulding Compound

Sheet Moulding Compound

Our compression molding process uses thermosetting polyester resin reinforced with glass fiber, a material that guarantees excellent mechanical and resistance characteristics.

Below are some of the main qualities of our product:

• Strength and dimensional stability: our thermosetting polyester resin, reinforced with glass fiber, ensures superior dimensional stability, maintaining the original shape and dimensions even under extreme mechanical loads

• High rigidity and resilience: The material offers considerable rigidity and resilience, making it ideal for applications requiring strength and durability. These properties allow the products to resist shock and stress without deforming

• High temperature resistance: Designed to operate in high temperature environments, our products can withstand temperatures up to 200°C. This makes them perfect for industrial applications in severe thermal conditions

• High quality molds: we use chromed steel molds, ideal for large-scale production. The chrome plating of the molds guarantees durability and precision in the molding process, ensuring an extended life cycle and constant quality of the final product

Injection Moulding - Thermoplastic

Injection Moulding - Thermoplastic

Polirim offers high quality solutions for a wide range of industrial applications. Our injection process is optimized to ensure maximum precision and product durability, using a variety of advanced thermoplastic materials.

Used materials:

• ABS (Acrylonitrile Butadiene Styrene): a versatile and resistant polymer, ideal for applications requiring high rigidity and dimensional stability

• PC-ABS (Polycarbonate-Acrylonitrile Butadiene Styrene): combines the properties of PC and ABS to offer an excellent balance of strength, impact resistance and machining ability

• ASA (Acrylonitrile Styrene Acrylate): characterized by excellent resistance to atmospheric agents and color stability, it is perfect for external applications

• PA6 (Polyamide 6) with glass fibre: offers high mechanical and thermal properties, suitable for components requiring high strength and rigidity

• PP (Polypropylene): known for its lightness and chemical resistance, it is widely used in many industrial sectors

• PP-EPDM (Polypropylene-Ethyl Propylene Diene Monomer): a combination that gives the material excellent elasticity and resistance to aging

Used materials:

• ABS (Acrylonitrile Butadiene Styrene): a versatile and resistant polymer, ideal for applications requiring high rigidity and dimensional stability

• PC-ABS (Polycarbonate-Acrylonitrile Butadiene Styrene): combines the properties of PC and ABS to offer an excellent balance of strength, impact resistance and machining ability

• ASA (Acrylonitrile Styrene Acrylate): characterized by excellent resistance to atmospheric agents and color stability, it is perfect for external applications

• PA6 (Polyamide 6) with glass fibre: offers high mechanical and thermal properties, suitable for components requiring high strength and rigidity

• PP (Polypropylene): known for its lightness and chemical resistance, it is widely used in many industrial sectors

• PP-EPDM (Polypropylene-Ethyl Propylene Diene Monomer): a combination that gives the material excellent elasticity and resistance to aging